Student rocketry to the Karman Line

Space Enterprise at Berkeley's mission has always been to reach the Kármán line with a liquid biopropellant rocket. This is an exciting endeavor that has never been accomplished before in global collegiate rocketry, that will challenge and push the bounds of our propulsion, structures, avionics, and manufacturing capabilities. Now, with SEB’s experience in building innovative liquid bipropellant rockets, we’re finally tackling this ultimate goal with Eureka-3.

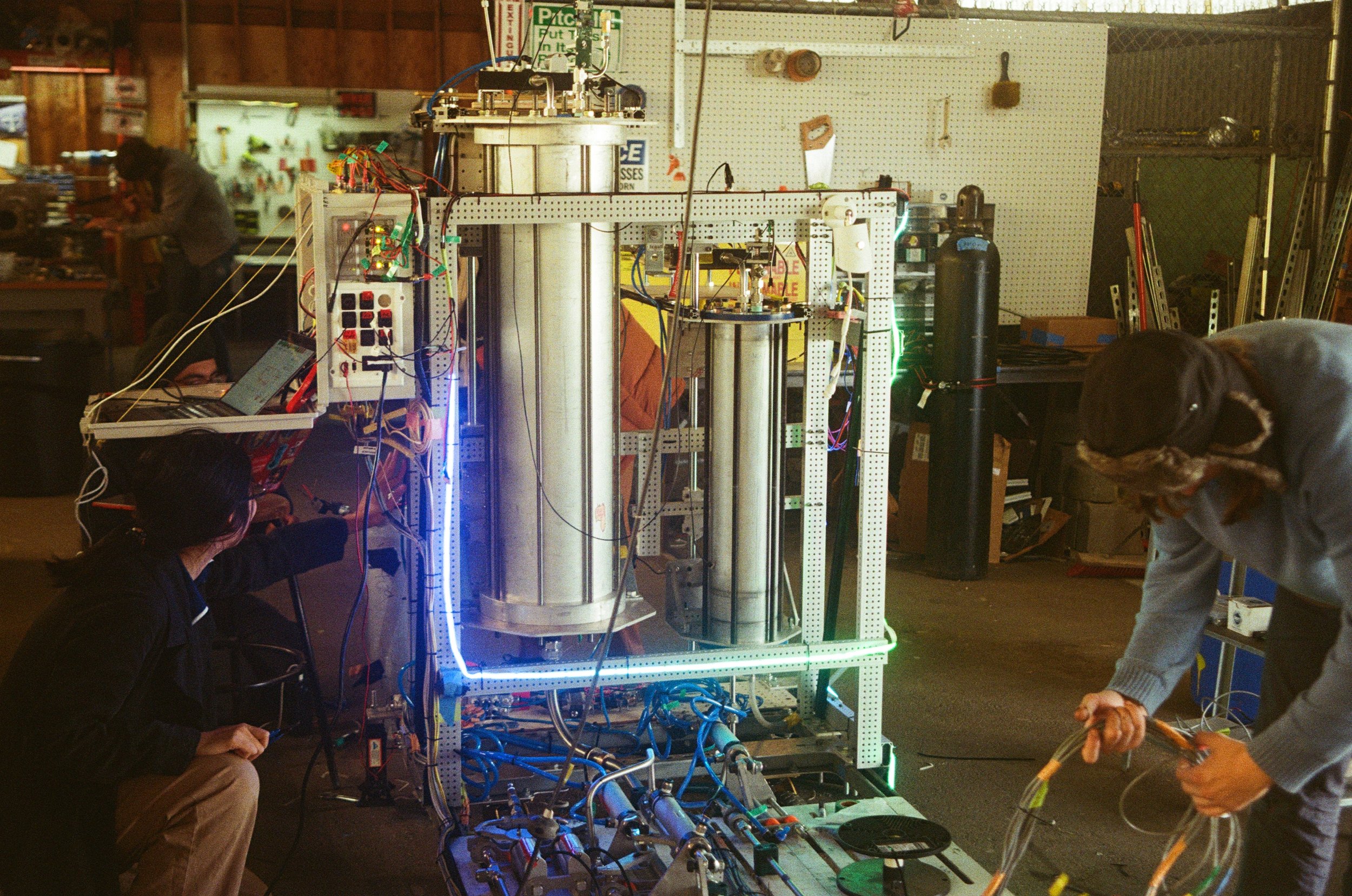

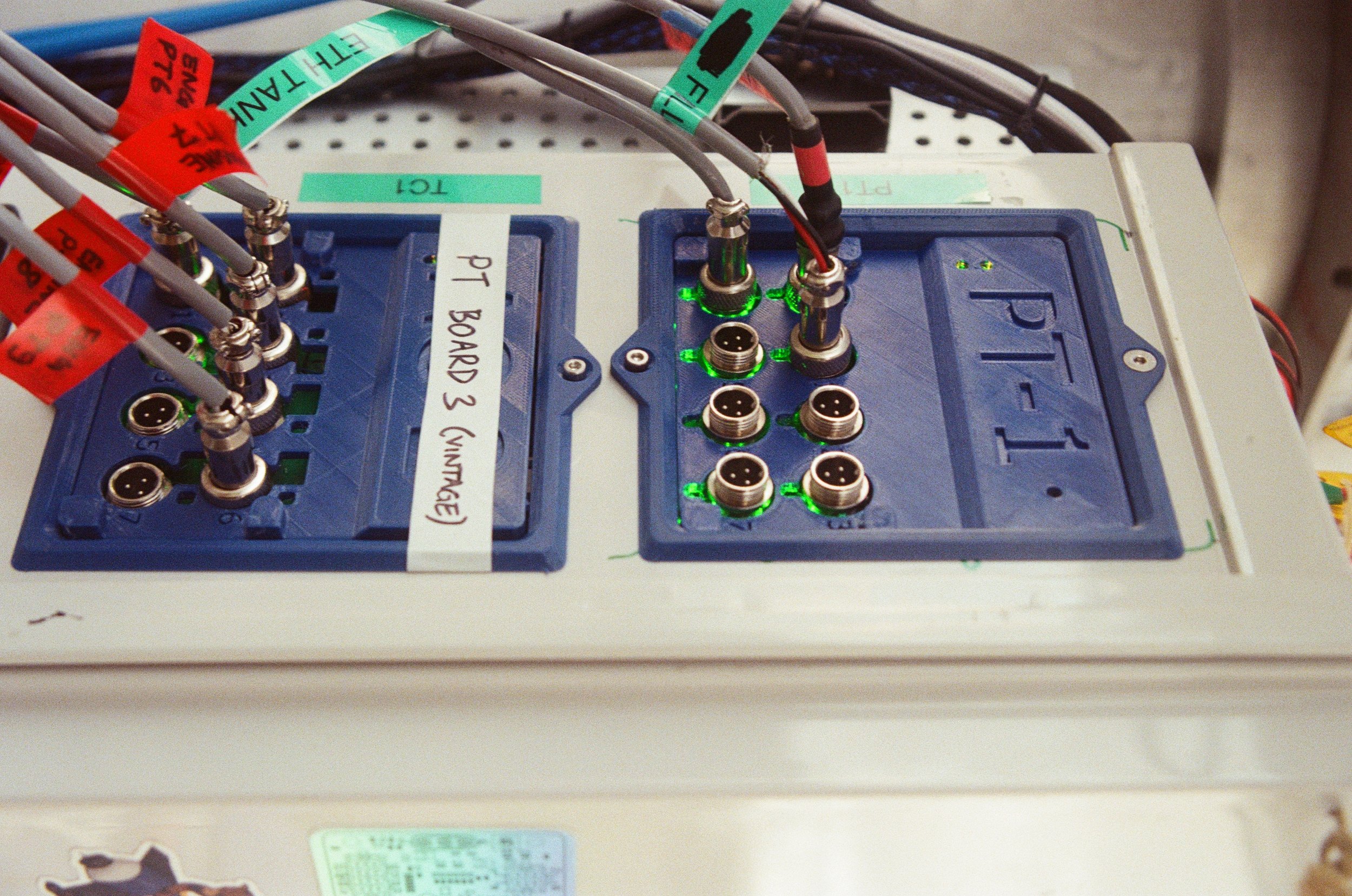

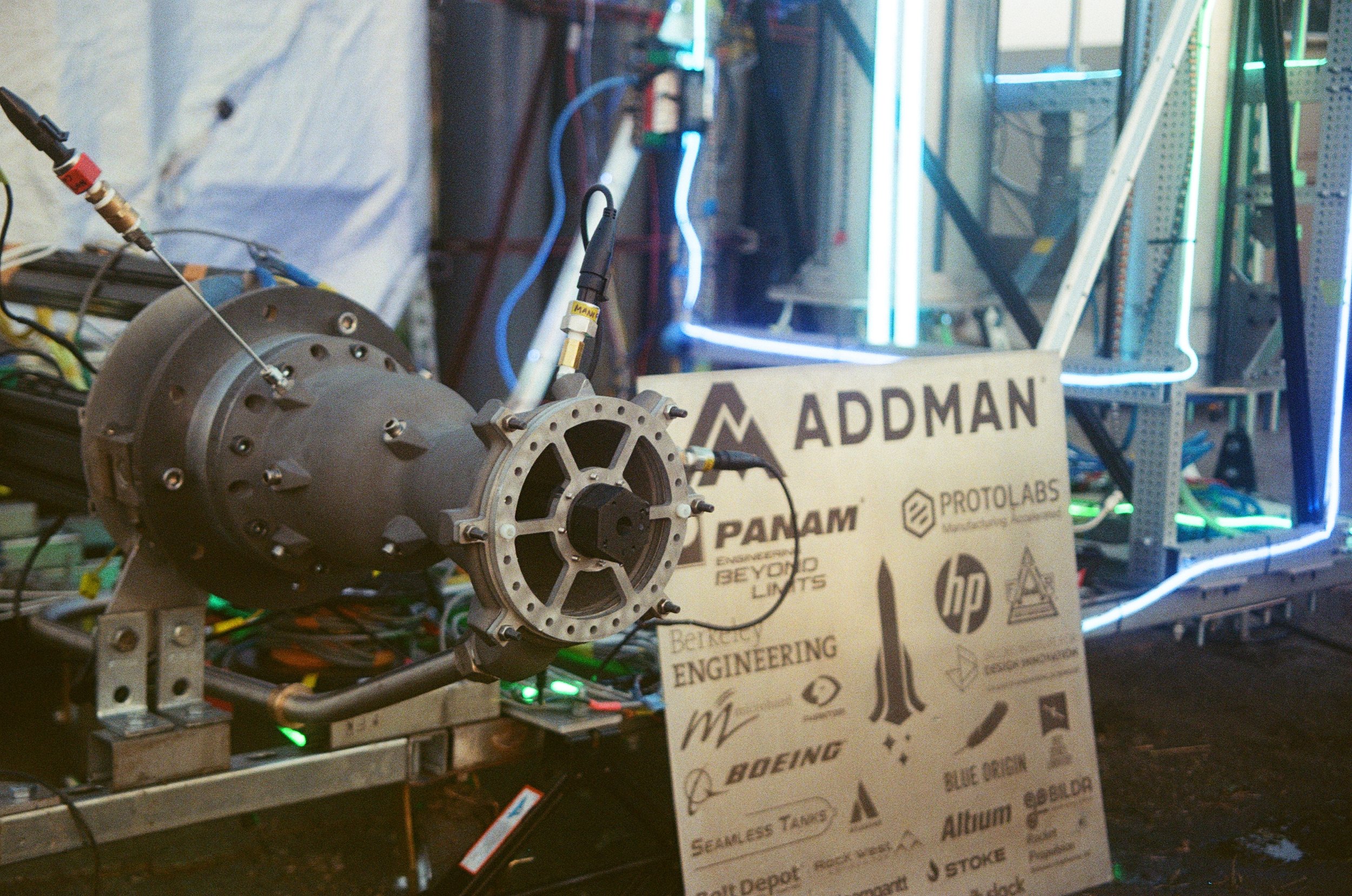

The Eureka-3 test stand. Featuring two custom tanks for Nitrous Oxide and IPA sized for an 8-second burn of a full-scale engine, this test stand showcases all of SEB’s propulsion, manufacturing, and avionics expertise, optimized to collect as much data as possible about all aspects of our propulsion system when we conduct testing. Our fill and flow procedures with this cart are fully remote and incorporate significant automation. Our past projects, the capacitive fill sensor and electronic regulator (E-Reg), are also crucial to this test stand, as their reliable performance and unique capabilities allow us to control the system to a greater extent.

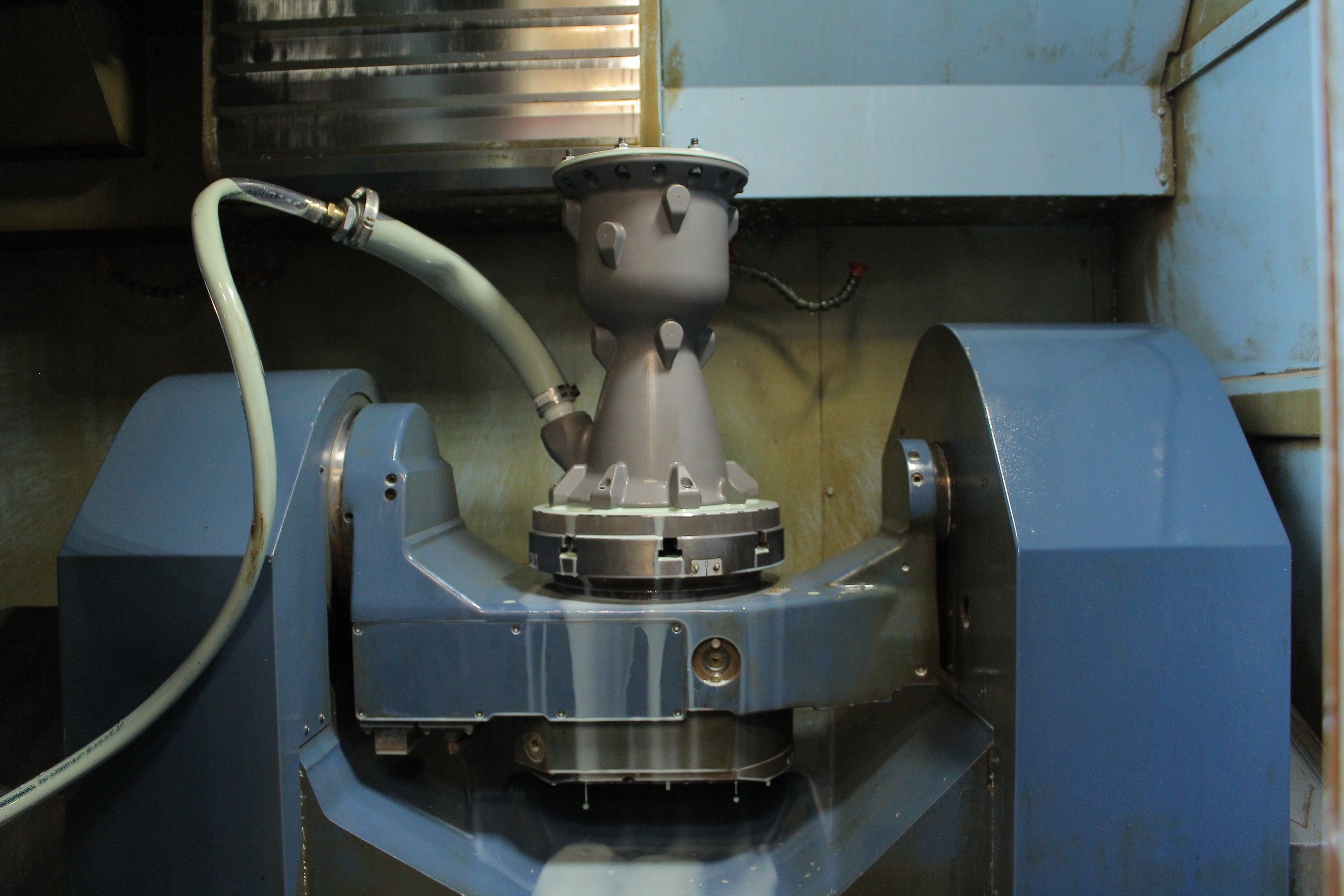

Our vertical test stand is another stepping stone for demonstrating Eureka-3’s propulsion system architecture. This test stand features coaxial concentric tanks, meaning that our fuel tank is fully contained inside our oxidizer tank. A piston allows the self-pressurization of nitrous oxide to also pressurize our IPA inside the fuel tank. This entire system was designed, built, and tested in 10 weeks, and we continue to iterate on it as we prototype components for the propulsion system that will ultimately take Eureka-3 to the Karman Line.

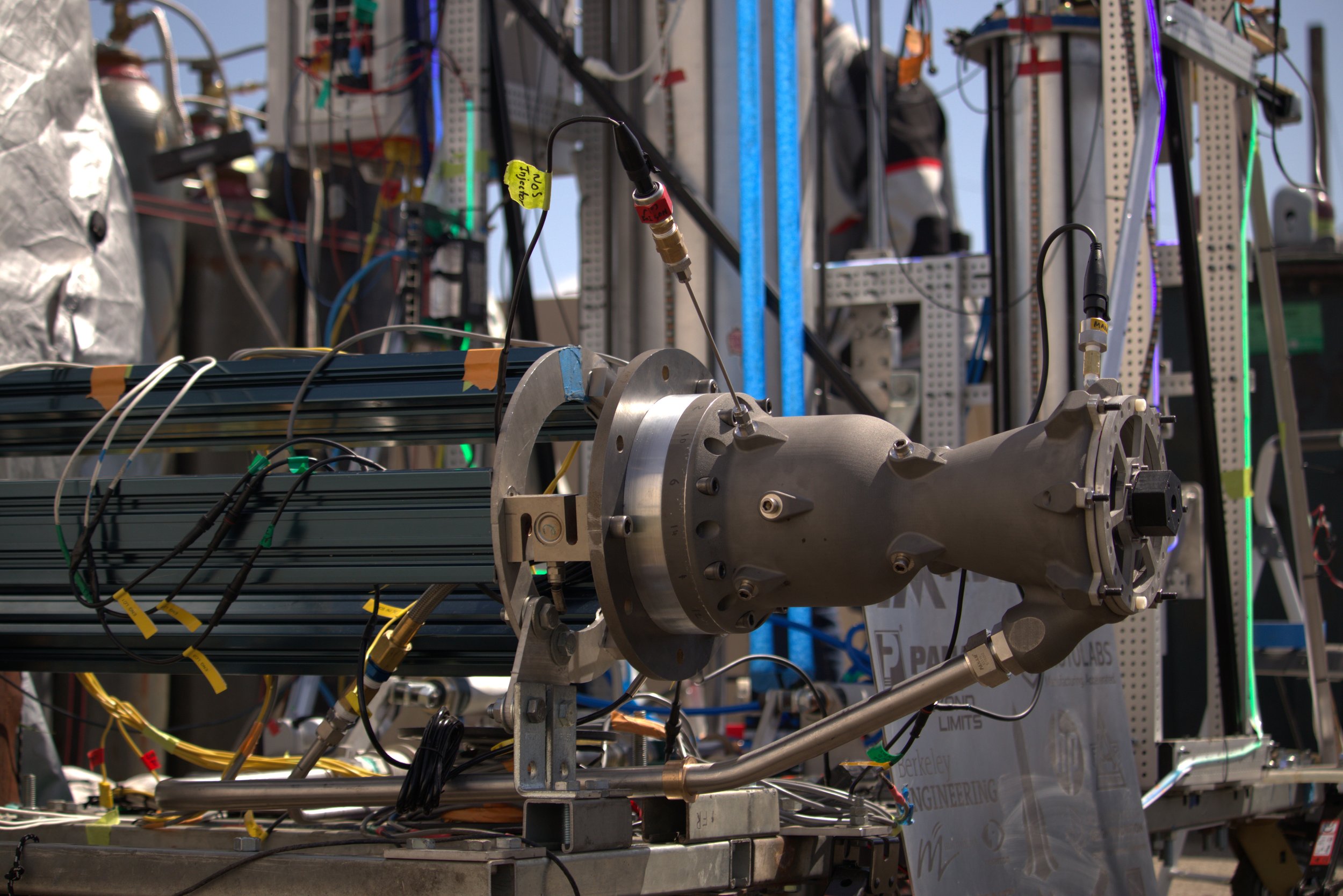

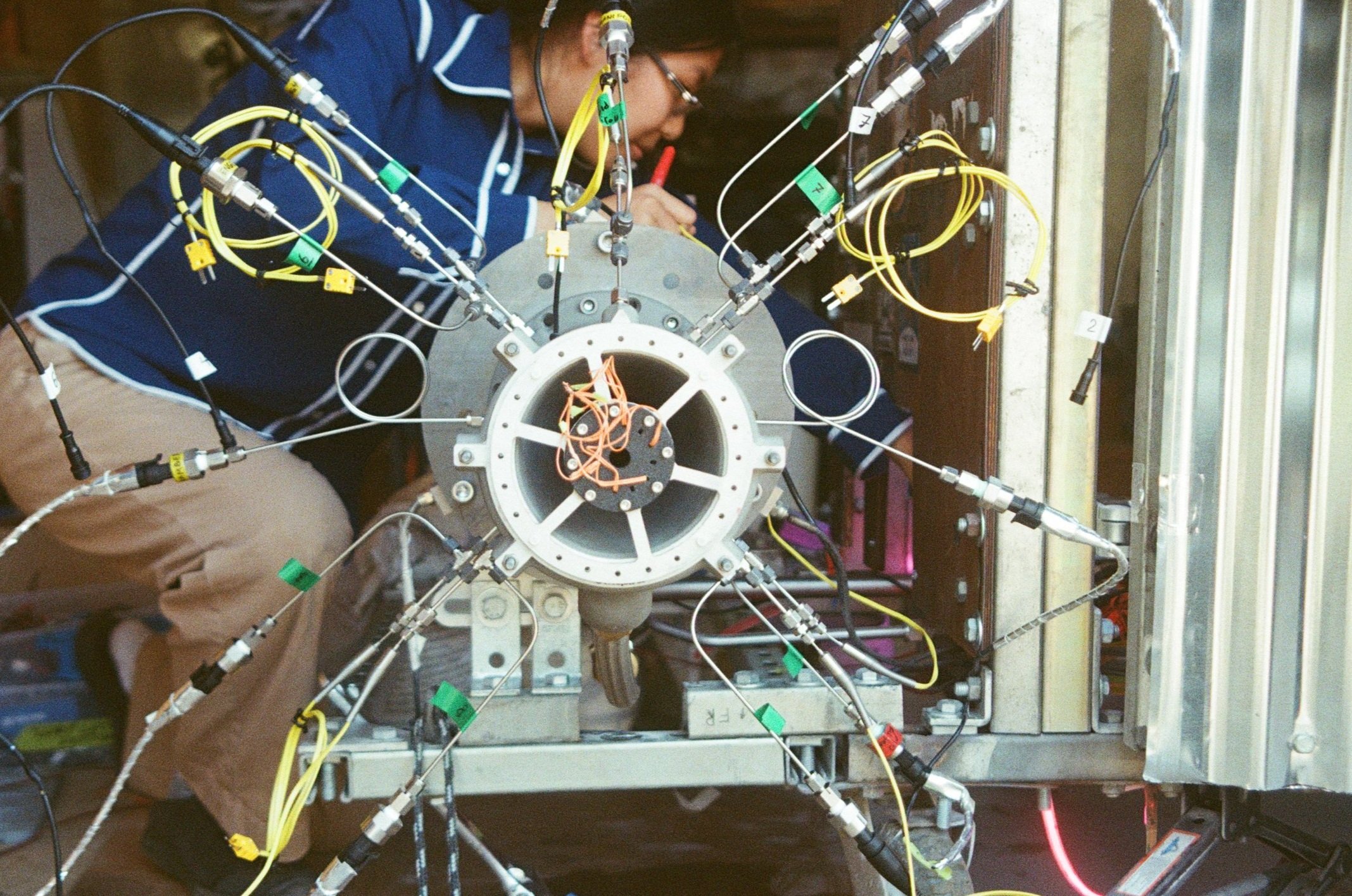

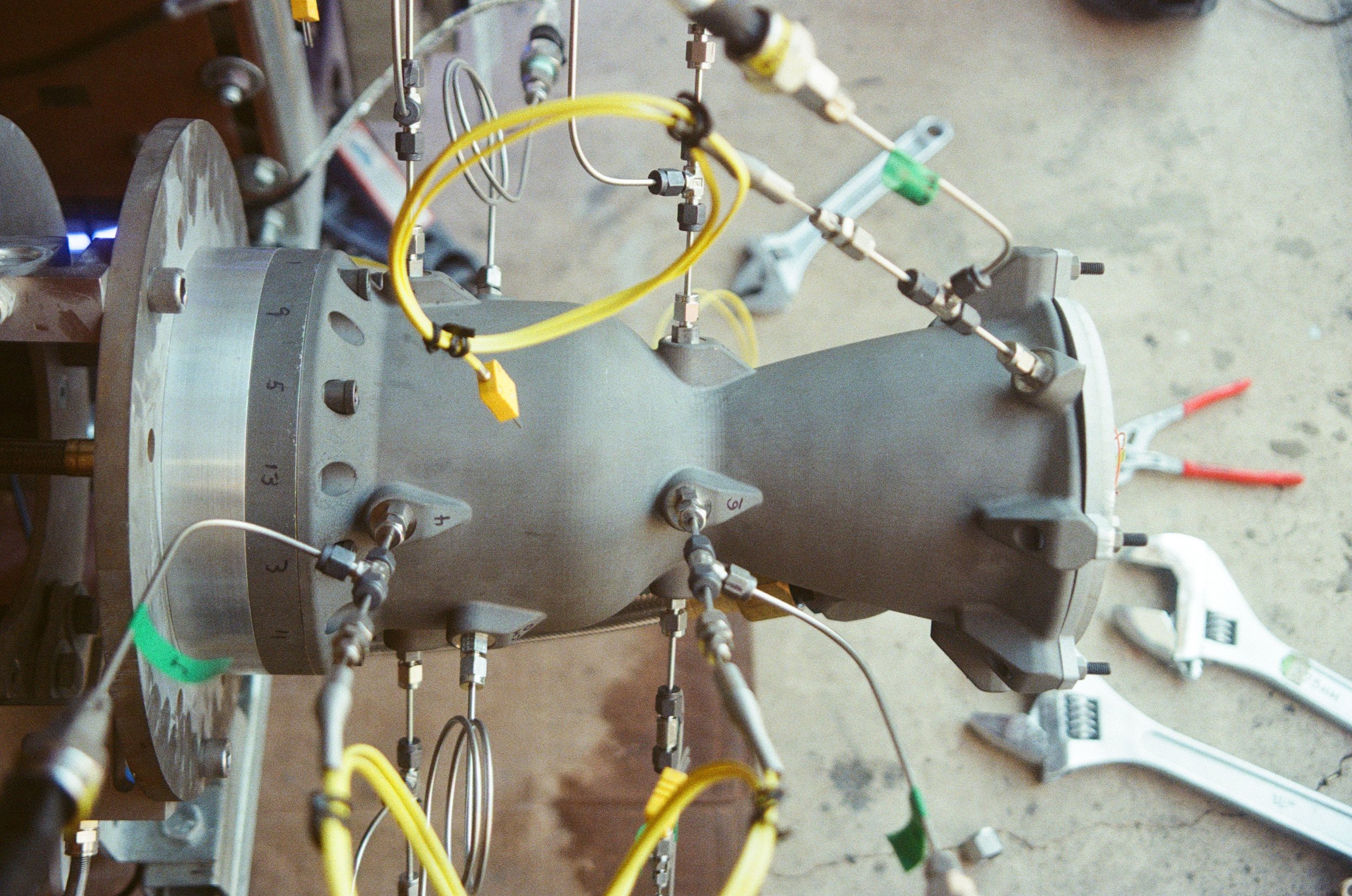

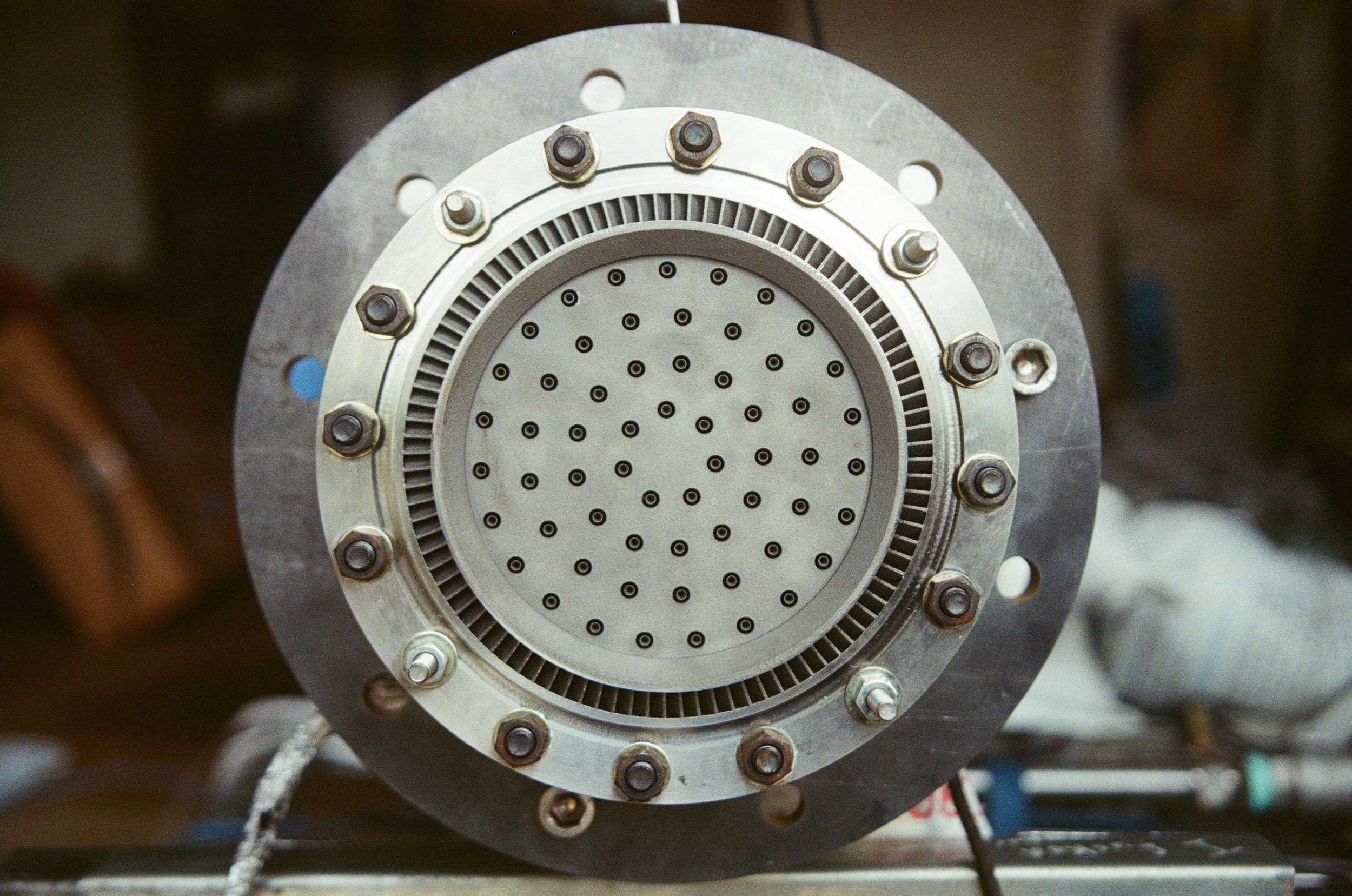

The beginning of the Eureka-3 testing campaign: two ablative engine static fires leading up to the first static fire of Heavybulb, our regeneratively-cooled, 3D printed engine. Heavybulb produced a record-setting thrust of 11kN, around 2600 pounds force, in this test. The huge amount of data collected from this test lets us iterate on the engine design, so that we design an even bigger, better engine.

Our ablative engine “Disposabulb” was used to test ignition and our feed system in our first time working with Nitrous Oxide and IPA. It performed well, with little ablation over two static tests. These tests helped us refine our procedures and better characterize our propulsion system before firing our regeneratively cooled engine.

With more than 3 years of testing, building, and launching liquid propulsion systems, Space Enterprise at Berkeley has begun the design, development, and testing campaign of Eureka-3. The current focus of development is set on the engine and nitrous oxide-IPA blowdown propulsion system. The first iteration of Eureka-3’s engine, Heavybulb, is regeneratively cooled with nitrous oxide and 3D-printed out of Inconel-718.

If you want to support the development of Eureka-3, please consider donating to our team!